1

/

of

1

IMD

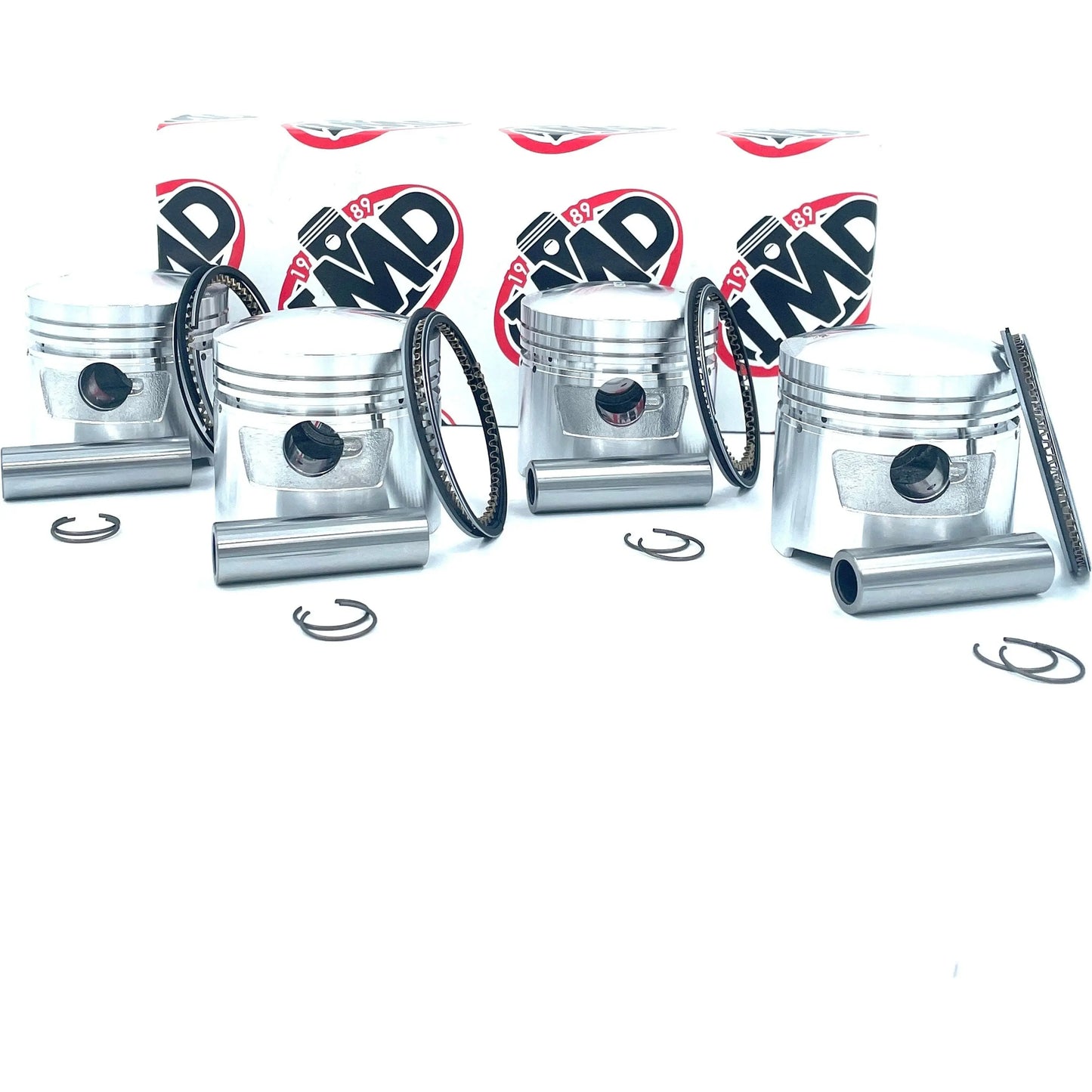

HONDA CB750 SOHC (392/410) HIGH COMPRESSION PISTON KITS (4)

HONDA CB750 SOHC (392/410) HIGH COMPRESSION PISTON KITS (4)

Regular price

£204.99 GBP

Regular price

Sale price

£204.99 GBP

Unit price

/

per

Tax included.

Shipping calculated at checkout.

Couldn't load pickup availability

HONDA CB750 SOHC 1976-1978 (392/410) PISTON KITS

*YOU CAN USE THIS IN A 300 TYPE ENGINE (FLAT TOP PISTON ENGINE), HOWEVER CERTAIN USA IMPORT MODELS HAVE DIFFERENT COMBUSTION CHAMBER SHAPE. PLEASE CONTACT US IF YOU BELIEVE YOUR ENGINE IS A US IMPORT, OR YOU WISH TO SEEK ADVICE BEFORE PURCHASE*

*IMD ACCEPTS NO LIABILITY IF CUSTOMER DOES NOT CHECK OR CONTACT BEFORE PURCHASE*

FITS CB750F1 CB750 F2 K7 K8

STANDARD COMPRESSION RATIO CB750F2 = 9.0:1

STANDARD BORE SIZE = 61mm

PLEASE CHECK SIZE BEFORE ORDERING

REPLACES: 392/410

WHAT IS INCLUDED:

PISTONS (4)

RING SETS (4)

CIRCLIPS (8)

PISTON PINS (4)

All new motorcycle items listed are aftermarket/pattern parts unless otherwise stated in description. Any reference made to original manufacturer's name or part numbers (O.E.M.) is done for information only and does not imply that the items are original.

Where possible all parts are listed by part number (O.E.M.). Please reference your parts list for the correct applications.

Please note: All motorcycles parts sold on this site need to be fitted by a qualified engineer using the correct appropriate equipment & machinery and using necessary technical manuals. No liability can be accepted for parts incorrectly fitted, and any failure of such parts after fitting.

Share